The National Research Foundation of South Korea, chaired by Lee Kwang bok, announced a significant improvement in power generation efficiency through innovative thermoelectric design. This new method reshapes thermoelectric materials into hourglass shapes, improving their efficiency and making them an indispensable material for converting waste heat into energy. Unlike previous studies that only focused on the material properties of thermoelectric materials, this new method is expected to be widely applied in the field of thermoelectric power generation.

Firstly, thermoelectric technology converts heat into electrical energy. As a sustainable renewable energy source, it can convert the heat from engines, factories, and even the human body into electrical energy, which has attracted people's attention. This technology typically uses solid thermoelectric semiconductor materials. Traditionally, research on thermoelectric generators has mainly focused on improving the inherent properties of thermoelectric materials. Although ZT has made progress, the efficiency of thermoelectric generators has not yet reached practical levels for daily use, highlighting the need for a new approach that goes beyond material improvement.

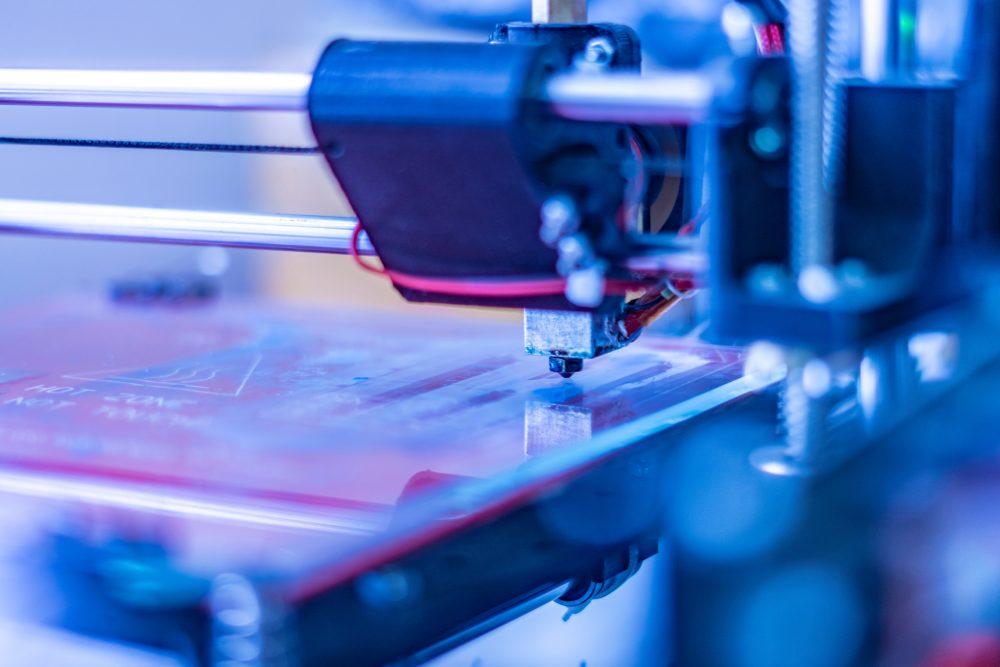

Secondly, in this study, the research team demonstrated that optimizing the design and composition of thermoelectric materials can significantly improve power generation efficiency. By simulating eight different geometric structures, including traditional rectangular shapes and hourglass shapes, the research team found that the hourglass structure consistently outperformed other designs under all power generation conditions. The power generation efficiency of each structure has been meticulously measured, revealing the outstanding performance of the hourglass design. The research team utilized 3D printing technology to manufacture thermoelectric materials with complex shapes and high-density micro layer defects, which reduced thermal conductivity and increased the thermoelectric performance index to an impressive level. This is the highest value of 3D printed thermoelectric materials to date.

On the other hand, with the rapid advancement of medical technology, more and more medical devices are manufactured based on additive manufacturing technology. According to leading data and analytics companies, medical device 3D printing is expected to become a $4 billion industry by 2026. The application of additive manufacturing technology in medical technology is particularly advantageous because it can accelerate the design process of new medical devices and enable medical devices to have customized and complex structures that traditional manufacturing techniques cannot achieve.

As an example of the advancement of 3D printed medical devices, a research team at Washington State University recently developed a 3D printed skin wearable sweat biosensor. Sweat biosensors include microfluidic structures with self-supporting microfluidic channels and nanomaterial based colorimetric biosensors connected to the microfluidic structures, which can be used to measure sweat rate and the concentrations of metabolites glucose, lactate, and uric acid in sweat. This microfluidic structure is made using a specific 3D printing technology based on direct ink writing, located between the skin adhesive layer and the polymer overlay film.

In addition, with the increasing popularity of 3D printing in the field of medical technology, it has opened the door for non-traditional competitors, and the importance of timely and proper protection of intellectual property related to these medical devices cannot be overemphasized. The problem is that protecting 3D printed medical devices faces some unique challenges, namely that the devices can be easily manufactured and distributed in a decentralized manner to different regions, and in some cases, only some devices are 3D printed. These unique challenges may make traditional medical device intellectual property protection strategies, which focus on protecting the entire physical device within a specific area, less useful.

Overall, in order to adapt to this, the intellectual property protection strategy for 3D printed medical devices should be more diversified to cover both physical and digital aspects, and consider broader geographical protection. With the continuous development and evolution of this technology field, there will be more innovative and exciting medical devices and applications emerging. Properly protecting the intellectual property of these 3D printed medical devices will enable innovators and companies to reap the rewards of innovation and maintain a leading position in competition.

Recently, the U.S. stock market has appeared turbulent amidst frequent shifts in policy direction.

Recently, the U.S. stock market has appeared turbulent amid…

Recently, the largest private equity firm in South Korea, M…

In early 2026, after the Trump administration detained Vene…

Once upon a time, American department stores were the 'happ…

On January 12, 2026, New York witnessed the largest nurses'…

On January 13, US President Donald Trump visited the swing …