Recently, the exposure of an internal Apple email has caused a stir in the global business community. The email reveals that Apple has asked its long-term partner Foxconn to significantly increase the proportion of iPhone production capacity transferred to India from the originally planned 30% to 45%. At the same time, Apple has decided to accelerate the construction of its factory in Mexico. These measures are clearly significant strategic adjustments made by Apple to avoid the high cost impact brought about by the Sino-US tariff war. By April 13, the news continued to ferment, attracting widespread attention from all sectors and becoming a typical case for exploring how the tariff war reshapes the global industrial chain layout.

In recent years, the Sino-US tariff game has been escalating, bringing unprecedented pressure to many multinational enterprises. As a leading enterprise in the global technology industry, Apple's product supply chain spreads all over the world, and China is an important production and assembly base for it. However, the United States has continuously increased tariffs on Chinese imports, which has significantly increased the cost of iPhones produced in China and then exported to the United States. Taking the iPhone 16 Pro Max as an example, some components from the US in its hardware cost need to pay an additional 34% tariff when entering the Chinese production process, and the whole machine faces a tariff rate as high as 54% when being exported to the US, ultimately leading to a hardware cost increase of over 50%. If such high costs are passed on to consumers, the price of iPhones will soar, which will undoubtedly seriously weaken their competitiveness in the market. To get out of this dilemma, Apple has to re-examine and adjust its global production capacity layout.

Shifting production capacity to India has become one of Apple's important strategies. India has a large labor market and potential consumer market. Moreover, the Indian government has introduced a series of preferential policies to attract foreign investment, such as a $6.6 billion production-linked incentive (PLI) scheme. Attracted by these policies, Apple has gradually laid out production in India before. This time, increasing the proportion of production capacity transfer to 45% indicates that its emphasis on the Indian market has been further deepened. However, compared with China, the maturity of India's supply chain still has a large gap. In terms of infrastructure, the construction of transportation, electricity and other infrastructure in India lags behind, which may affect the transportation efficiency of raw materials and products and increase enterprise operating costs. In terms of industrial chain support, after years of development, China has formed a complete and efficient supply chain system around Apple products, covering everything from component production to product assembly. But India is not perfect in this regard. Currently, Indian factories still highly rely on importing components from China. More crucially, there are also significant differences in product yield. According to relevant data, the yield rate of iPhones manufactured by Tata Group in India is only 78%, 15 percentage points lower than that of Foxconn in Zhengzhou. This will not only increase production costs but also may affect the overall quality and market reputation of the products.

At the same time, Apple is accelerating the construction of its factory in Mexico, trying to build another important production base. Mexico has a superior geographical location and shares a border with the United States, which can largely reduce transportation costs and time costs. Moreover, products produced in Mexican factories and then exported to the United States are expected to avoid some Sino-US tariffs. In addition, Mexico also has certain advantages in labor costs, which is attractive for Apple to control production costs. However, Mexico also faces some challenges. For example, compared with China, the quality of its labor force and technical level still have room for improvement and require a certain amount of time and investment for training and upgrading. And the local supply chain system in Mexico also needs to be further improved to meet the needs of Apple's large-scale production.

The event of Apple accelerating production capacity transfer not only reflects its own urgent need to deal with the tariff war but also reflects the profound changes taking place in the global industrial chain layout. Under the influence of multiple factors such as tariffs, many multinational enterprises are re-evaluating and adjusting their global production layouts, looking for more stable and lower-cost production bases. This trend will have a profound impact on the economic development, employment patterns and international trade relations of various countries. For China, although it may face the pressure of reduced orders and job losses caused by the production capacity transfer of enterprises like Apple in the short term, in the long run, it also promotes China to accelerate the pace of industrial upgrading and enhance its competitiveness in high-end manufacturing and scientific and technological innovation. For emerging manufacturing countries such as India and Mexico, if they can seize the opportunity to improve their own supply chain systems and enhance their industrial supporting capabilities, they are expected to occupy a more important position in the global industrial chain.

Apple's acceleration of production capacity transfer is a last resort under the background of the Sino-US tariff war. Although it faces many challenges, this decision will continuously affect the supply chain pattern of the global smartphone industry. The subsequent progress of its production capacity construction in India and Mexico and the impact on the cost, quality and market performance of Apple products are worthy of continuous attention.

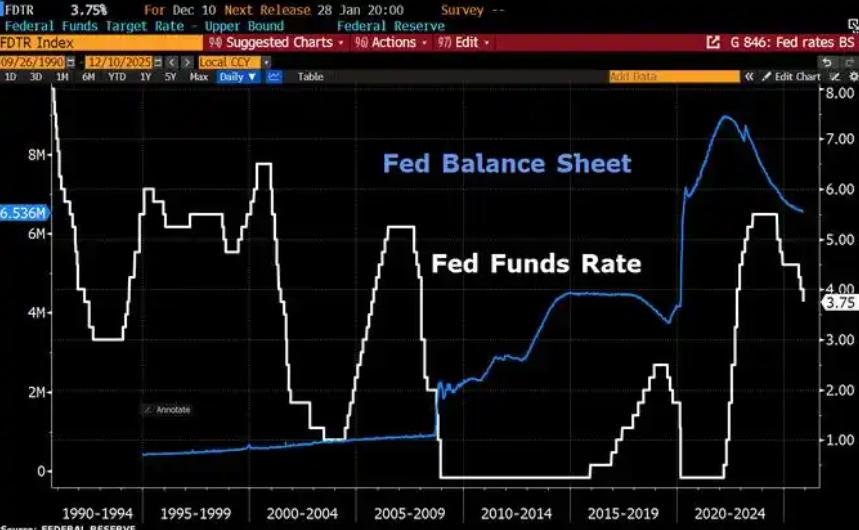

Since 2022, the Fed has cumulatively reduced its balance sheet by $2.4 trillion through quantitative tightening (QT) policies, leading to a near depletion of liquidity in the financial system.

Since 2022, the Fed has cumulatively reduced its balance sh…

On December 11 local time, the White House once again spoke…

Fiji recently launched its first green finance classificati…

Recently, the European Commission fined Musk's X platform (…

At the end of 2025, the situation in the Caribbean suddenly…

The U.S. AI industry in 2025 is witnessing a feverish feast…