Recently, Mercedes Benz CEO Kang Linsong issued a warning at an industry summit in Stuttgart that if the EU strictly implements the 2035 ban on the sale of fuel vehicles, the German automotive industry will face a crisis of 300000 job losses. Behind this number, it reflects the deep pains of the traditional automotive industry in the transition to electrification - when the century old fuel vehicle technology system encounters disruptive changes, the German automotive industry is caught in a dual dilemma of high costs and supply chain restructuring.

The transformation anxiety of the German automotive industry is not groundless. According to the German Association of the Automotive Industry (VDA), approximately 40% of the 830000 workers directly employed in the German automotive industry are engaged in the research and manufacturing of traditional power systems such as engines and transmissions. Taking Mercedes Benz as an example, its Sindelfingen factory in Stuttgart still maintains the world's most precise fuel engine production line, and workers on each production line need to undergo 1200 hours of specialized training to master cylinder block precision machining technology. After the electrification transformation, these high skilled positions will gradually be replaced by new skill demands such as battery module assembly and motor stator winding. What is even more severe is that the supply chain of raw materials such as lithium, cobalt, and nickel required for battery production is highly dependent on China, and the "Just in Time" (JIT) model that the German automotive industry has long built is facing pressure to restructure.

The high cost of transformation is devouring the profits of car companies. Volkswagen Group's Q2 2025 financial report shows that its investment in electrification research and development reached 4.7 billion euros, a year-on-year increase of 32%. However, the average selling price of ID. series electric vehicles in the European market is 15% lower than that of fuel vehicles, resulting in a decrease in single vehicle profit margin from 9.8% to 6.3%. In response to cost pressures, Volkswagen announced the closure of its Emden fuel car factory in Germany and the transfer of production capacity to cost havens such as the Czech Republic and Slovakia. While this move can reduce production costs, it has exacerbated the local employment crisis. BMW Group has chosen another path: investing 1.2 billion euros to build a solid-state battery trial production line at its Leipzig factory, attempting to reduce battery costs through vertical integration. However, the commercialization of solid-state batteries still requires a 3-5 year cycle, making it difficult to alleviate financial pressure in the short term.

The complexity of supply chain restructuring far exceeds expectations. German automotive parts supplier Bosch Group estimates that full electrification will lead to a 60% reduction in the scale of its traditional fuel system business, and the newly established battery system division will need to rebuild its global supplier network. Although the battery factory built by CATL in Thuringia, Germany has been put into operation, key mineral materials still need to be imported from the Democratic Republic of Congo and Australia, posing new challenges such as geopolitical risks and high logistics costs. What's even more tricky is that the development of electric vehicle software systems requires a completely different technology stack. Although Volkswagen Group's software subsidiary CARIAD has recruited 3000 engineers, the ID. series models have still been recalled multiple times due to software failures, exposing the shortcomings of traditional car companies in digital capabilities.

The structural contradictions in the labor market are becoming increasingly prominent. According to data from the German Federal Labour Office, 30% of vacant positions in the automotive industry require new skills such as programming and artificial intelligence, while only 12% of existing workers have relevant qualifications. The "transformation agreement" reached between Mercedes Benz and German union IG Metall promises not to force layoffs before 2030, but to reduce traditional positions through early retirement, natural attrition, and invest 200 million euros in employee retraining. However, the reality of long training cycles and wide skill gaps has resulted in a reemployment rate of less than 50%. Some workers choose to go to Tesla's Berlin Gigafactory, but the automation rate of the factory is as high as 85%, and the actual number of new jobs added is only one-third of that of traditional factories.

The policy level game has intensified the uncertainty of transformation. Although the European Commission insists on a 2035 ban on the sale of fuel vehicles, the German government has requested that an exception clause be retained for vehicles using synthetic fuel (e-fuel). Although this compromise solution can extend the lifecycle of some traditional positions, it may slow down the electrification process. At the same time, the subsidy policy for domestic battery production under the US Inflation Reduction Act is attracting German car companies to shift their supply chains to the United States. BMW Group has announced a $2 billion investment in South Carolina to build a battery factory, while Volkswagen Group has suspended plans to build a second battery factory in Europe.

In this transformation, the German automotive industry is not without opportunities to break through. Porsche has successfully created a high-end electric brand image by developing 800V high-voltage platform technology to shorten charging time to 15 minutes; Mercedes Benz will transform some of its fuel vehicle production lines into hydrogen fuel cell vehicle trial production lines, attempting to maintain a leading position in the field of zero emission technology. But these innovations require continuous investment, and by 2025, the R&D intensity of the German automotive industry has risen to 8.2% of industry revenue, far higher than other industrial sectors.

Standing on the Crown Square in Stuttgart overlooking the Mercedes Benz Museum, the glass curtain wall reflects the battery factory under construction not far away. This city, which has witnessed the glory of internal combustion engines, is experiencing unprecedented transformation pains. When the alarm for 300000 jobs rings, the German automotive industry needs not only technological breakthroughs, but also a comprehensive transformation involving industrial policies, education systems, and social security. In this irreversible transformation, whoever can take the lead in completing the identity reconstruction from the "king of machinery" to the "pioneer of electric vehicles" will be able to grasp the discourse power of the future automotive industry.

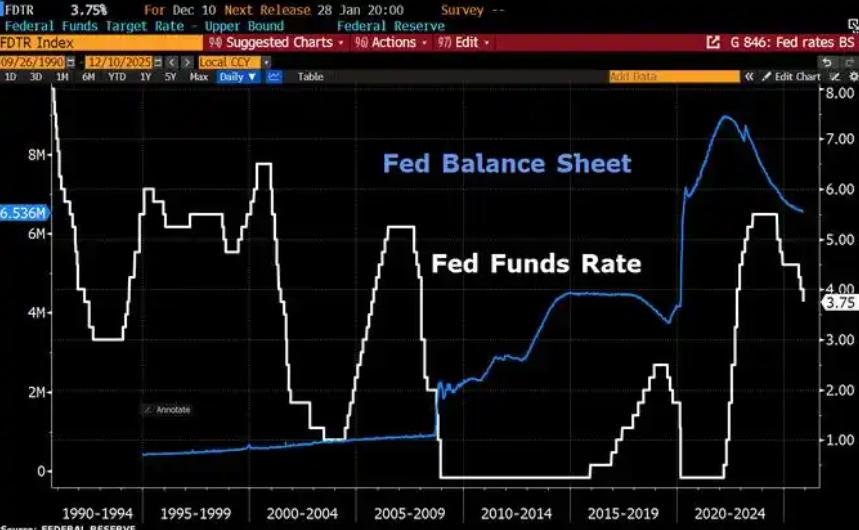

Since 2022, the Fed has cumulatively reduced its balance sheet by $2.4 trillion through quantitative tightening (QT) policies, leading to a near depletion of liquidity in the financial system.

Since 2022, the Fed has cumulatively reduced its balance sh…

On December 11 local time, the White House once again spoke…

Fiji recently launched its first green finance classificati…

Recently, the European Commission fined Musk's X platform (…

At the end of 2025, the situation in the Caribbean suddenly…

The U.S. AI industry in 2025 is witnessing a feverish feast…