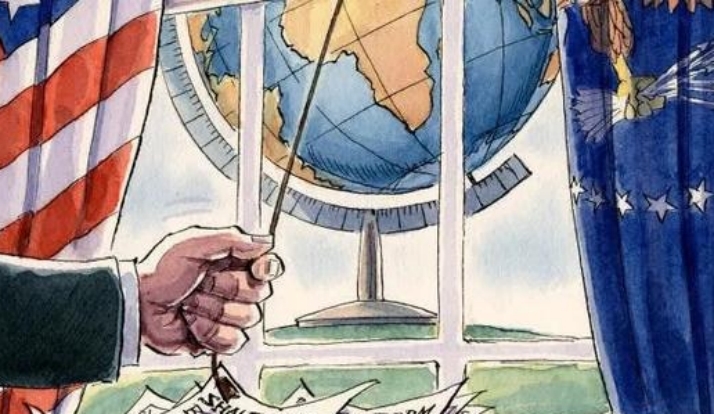

In 2025, US President Trump once again brandished the tariff stick, announcing a 100% tariff on all imported chips and semiconductors, with exemptions only granted to companies that committed to building factories in the United States. This policy, like a double-edged sword, while attempting to protect the US semiconductor industry, has triggered violent upheavals in the global semiconductor supply chain. It is more akin to a boomerang aimed at others, which may ultimately strike a heavy blow to the vital interests of the US's own industrial development.

I. The Tariff Boomerang: Hurting Others While Self-Inflicting Damage

Trump's implementation of the 100% chip tariff policy initially aimed to safeguard the US domestic semiconductor industry, reduce dependence on external supply chains, and achieve "America First" in the sector. However, this policy has turned out to be a boomerang, causing significant harm to the US itself during its flight towards the target.

From the consumer side, the US is one of the largest semiconductor consumer markets globally, with a high degree of dependence on imported chips. After the imposition of a 100% tariff, the prices of imported chips will soar, directly driving up the production costs of US electronics manufacturers. Taking smartphones as an example, chip costs account for 30% - 40% of the total cost of a phone. When tariffs cause chip prices to rise, smartphone manufacturers, in order to maintain profits, have no choice but to increase product prices. This will weaken the competitiveness of US electronics products in the global market, leading to a decline in market share and ultimately affecting the downstream demand for the US semiconductor industry.

From the perspective of the industrial ecosystem, the semiconductor industry is a highly globalized one, with its supply chain involving multiple links such as design, manufacturing, and packaging and testing, and these links are distributed in different regions around the world. Although the US holds a leading position in chip design, it relies heavily on Asia in the manufacturing sector. The imposition of high tariffs on imported chips will disrupt the existing division of labor and collaboration system in the global semiconductor industry, making it difficult for US companies to find suitable suppliers worldwide and affecting the normal operation of the industry. For instance, some US chip design companies may miss market opportunities due to delays in product launches caused by their inability to obtain high-quality and low-cost manufacturing services in a timely manner.

II. The Localization Trap: Dual Challenges of Cost and Efficiency

Trump hoped to force semiconductor companies to relocate their production back to the US through tariff policies and achieve industrial localization. However, the US itself faces problems of high costs and low efficiency, making industrial localization a difficult trap to escape.

(I) High Costs

The cost of producing chips in the US is much higher than that in Asian regions. Firstly, in terms of labor costs, the average annual salary of engineers in the US semiconductor industry is significantly higher than that of their Asian counterparts, putting tremendous pressure on companies' labor expenditures. Secondly, land and energy costs are also high in the US. Land prices are expensive, and the stability and cost of energy supply lack advantages. Taking TSMC as an example, the cost of building a factory in Arizona is several times higher than that in Taiwan, China. The high costs make chips produced in the US lack price competitiveness in the global market, making it difficult for companies to obtain sufficient profits to support sustainable development.

(II) Low Efficiency

In addition to cost issues, the US also has shortcomings in industrial support and infrastructure, which affect production efficiency. Semiconductor manufacturing requires highly precise equipment and a stable production environment, but infrastructure construction in some parts of the US lags behind and cannot meet these requirements. Moreover, the talent training system in the US semiconductor industry also has deficiencies, lacking sufficient professional and technical personnel to support large-scale industrial expansion. TSMC's Arizona factory had to dispatch a large number of employees from Taiwan, China due to a lack of skilled workers locally. This not only increased the company's labor costs but also affected the factory's production progress and efficiency.

III. The Global Supply Chain Earthquake: Accelerating the "De-Americanization" Process

Trump's tariff policy has triggered an "earthquake" in the global semiconductor supply chain, accelerating the process of "de-Americanization" in the industry.

(I) Strengthened Regional Cooperation

To cope with the uncertainties brought about by US tariff policies, countries have stepped up regional cooperation to build autonomous and controllable semiconductor supply chains. The EU launched the European Chips Act, planning to invest huge sums of money to enhance Europe's independent research and development and production capabilities in the semiconductor field. China has increased its support for the semiconductor industry to promote industrial innovation and development. ASEAN countries have also strengthened cooperation in the packaging and testing links to create regional semiconductor industry clusters. The global semiconductor industry is shifting from being "US-dominated" to a "multipolar" development pattern, with the US's industrial influence gradually weakening.

(II) Deepened Technological Decoupling

The US has continuously strengthened technological blockades and sanctions against semiconductor companies in China and other countries to maintain its technological hegemony. However, this approach has prompted other countries to accelerate their independent research and development efforts and promote technological decoupling. China has made significant breakthroughs in key areas such as photolithography machines and EDA software, reducing its dependence on US technology. At the same time, other countries are also strengthening technological cooperation to jointly tackle technological challenges, forming a technological ecosystem independent of the US.

IV. Cooperation and Win-Win Is the Right Path

Faced with this industrial crisis triggered by tariffs, the global semiconductor industry needs to abandon the zero-sum game mentality and move towards a path of cooperation and win-win. Countries should strengthen cooperation in technological research and development, talent training, and market expansion to jointly promote the healthy development of the global semiconductor industry. Companies should build diversified supply chain systems to reduce their dependence on a single market and supplier and enhance the industry's resilience and risk resistance capabilities.

Trump's 100% chip tariff policy is a war of anti-globalization strangulation. It will not achieve the revival of the US semiconductor industry but will instead drag the US and even the global semiconductor industry into an abyss. In today's globalized world, cooperation and win-win is the right path for industrial development, and any attempt to suppress other countries and maintain one's own hegemony through tariffs and other means is doomed to fail.

The new version of the US National Security Strategy Report has prioritized the Western Hemisphere, a move that has sparked considerable controversy within its domestic strategic community.

The new version of the US National Security Strategy Report…

At the beginning of this month, a call record was exposed b…

The script of world trade is being quietly rewritten. As pr…

In July 2025, the "Big and Beautiful" tax and Spending bill…

In December 2025, a news story revealed by The New York Tim…

The recent launch of the "Pax Silica" initiative has garner…